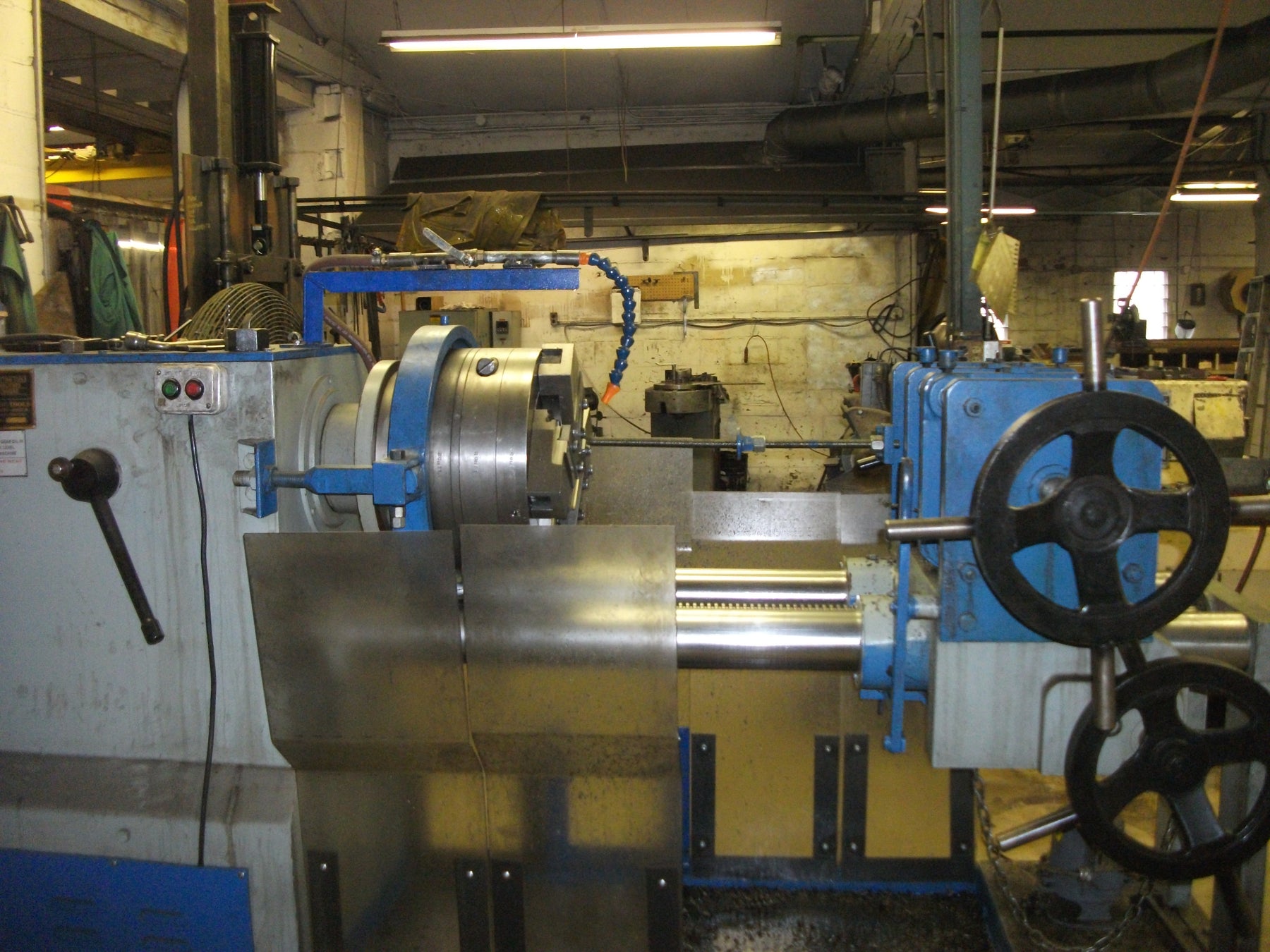

Anchor Bolt Threading Processes

When you need Anchor Bolts, we offer two different types of threading processes:

Roll threading is a cold forming process where a blank having an outside diameter between the major and minor diameters of the finished thread is rolled between hardened steel dies. The dies penetrate the blank to form the thread roots and displace material radially outward to form the crests. Unlike cut threading, metal is neither removed nor wasted, but displaced.

The cold forming process strengthens the threads in three ways: tension, shear, and fatigue resistance. The grain structure of the thread is not cut. Instead it is reformed in continuous unbroken lines following the thread contours. Rolled threads have increased resistance to stripping because of the improved grain flow.

Cut threading is a process where material is removed or cut away from around bar. Cut threading is advantageous for short runs, large diameter bolts, and some special materials. Cut threading has a shorter set-up but longer threading time per bolt.

Whitelaw Rigging manufacturers roll thread bolts in 5/8”, 3/4”, 1” and 1-1/4" diameters. All standard diameters are available cut thread. Both cut and roll threaded bolts meet current ASTM standards for non-headed bolts.

If you would like more information, you can call us at 800-543-8464 or email us at sales@WhitelawRigging.com. We are here to assist with all your anchor bolts needs.